Hammer Mill For Feather

.jpg)

Efficiency Enhancement in Hammer Mills through

2024年9月25日 Hammer mill is widely used in feed production due to its strong applicability to raw materials, simple structure and ease of handling [1–4] Hammer and sieve are the two 2023年2月14日 Hammer mills operate on the basic principle that most materials will crush, shatter or pulverize upon impact This is accomplished by a simple four step process: Material Intro to Size Reduction Schutte Hammermill2023年8月22日 Hammer mills use large rotating drums with protruding metal bars (ie, hammers) that impact the material at high velocity to shatter and tear material particles Optimizing hammer mill performance through screen Bühler’s horizontal hammer mill is for pregrinding and postgrinding in animal feed production, including pet foods and fish feed, as well as grain milling and other material size reduction processesHorizontal Hammer Mill Grinding System

.jpg)

Back to Basics Hammer Milling and Jet Milling

This article gives a detailed description of hammer mill and jet mill operation, and describes how to characterize the feed material and control product particle size2014年4月9日 There are numerous hammer designs available in industry, variations in hammer mill drum speeds and many combinations of screen selection in multiple stage processes to be considered In this paper, the Full article: Optimizing hammer mill performance 2020年8月8日 The last step of the process was the grinding of feathers in a hammer mill (Prestatti, capacity 4000 kg/hour) Figure 1 shows the steps for processing the HFMInfluence of Process Parameters and Raw Material on the4 天之前 Our industrial hammer mills or grinders are “made in Germany” We use only highquality components, such as our 6axis rotor design Based on our many years of experience, we have optimized our mills: They are Efficient Hammer Mills and Grinders Made in

CFB石灰石脱硫剂制备64.jpg)

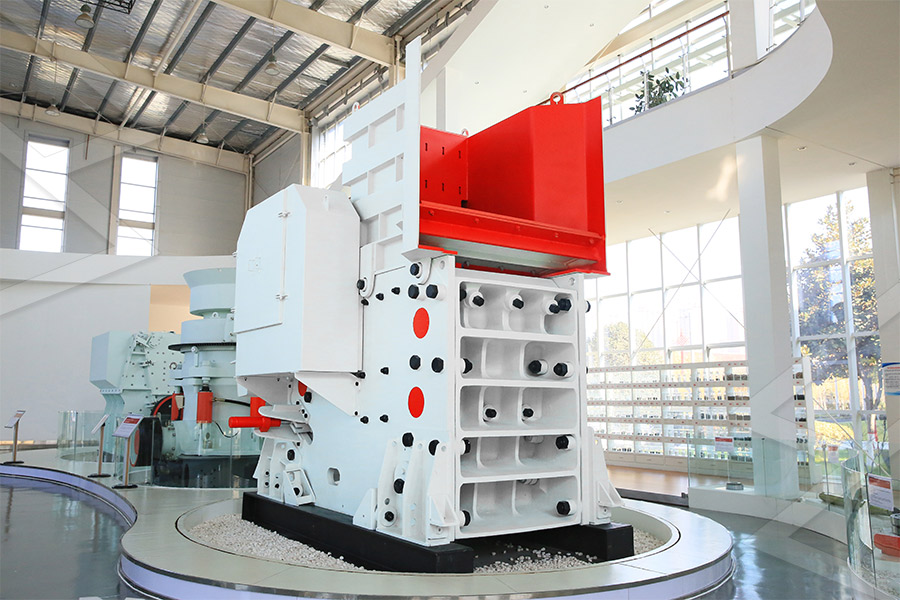

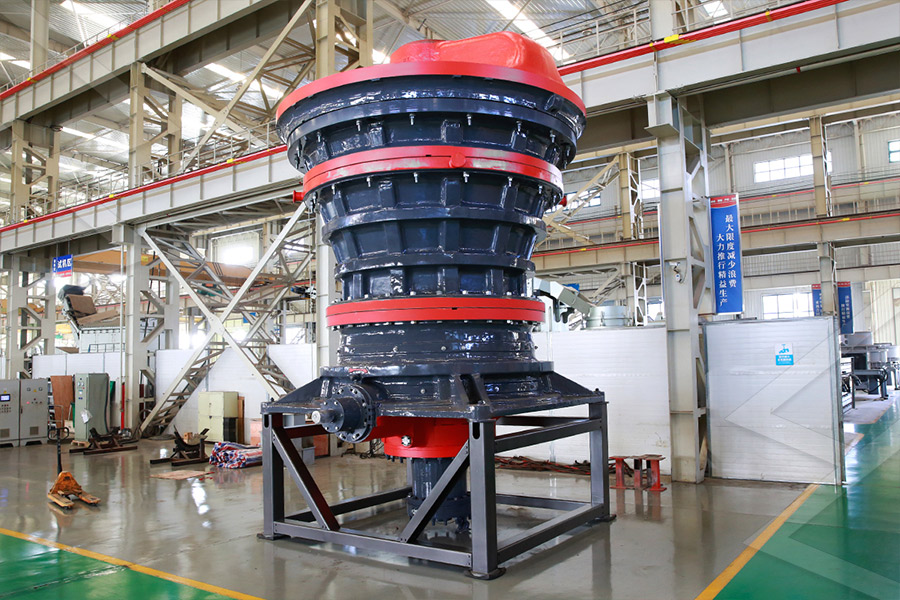

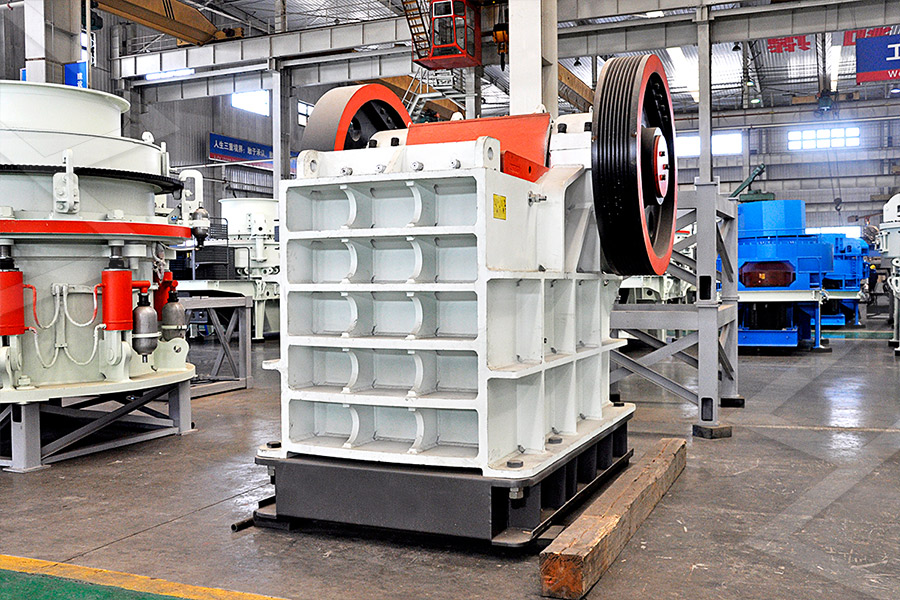

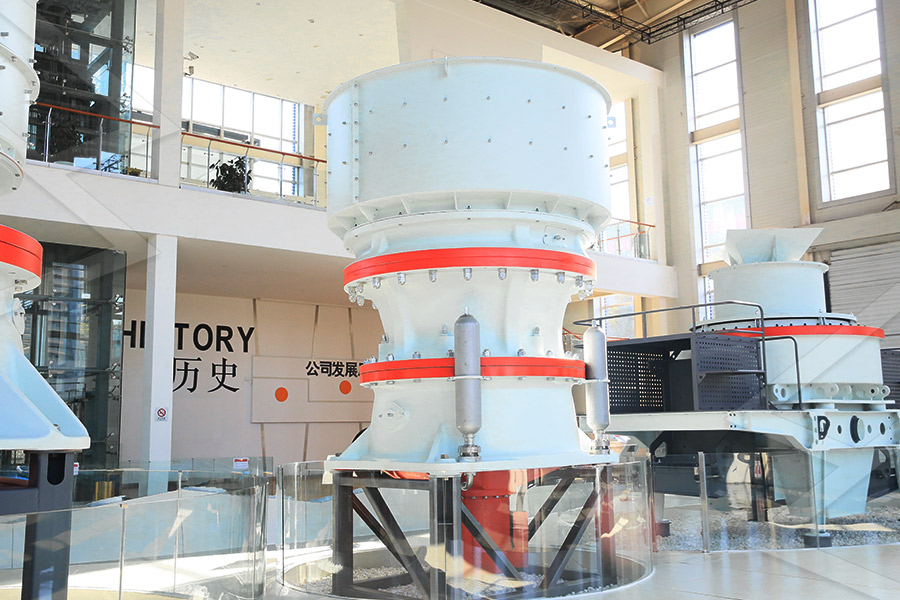

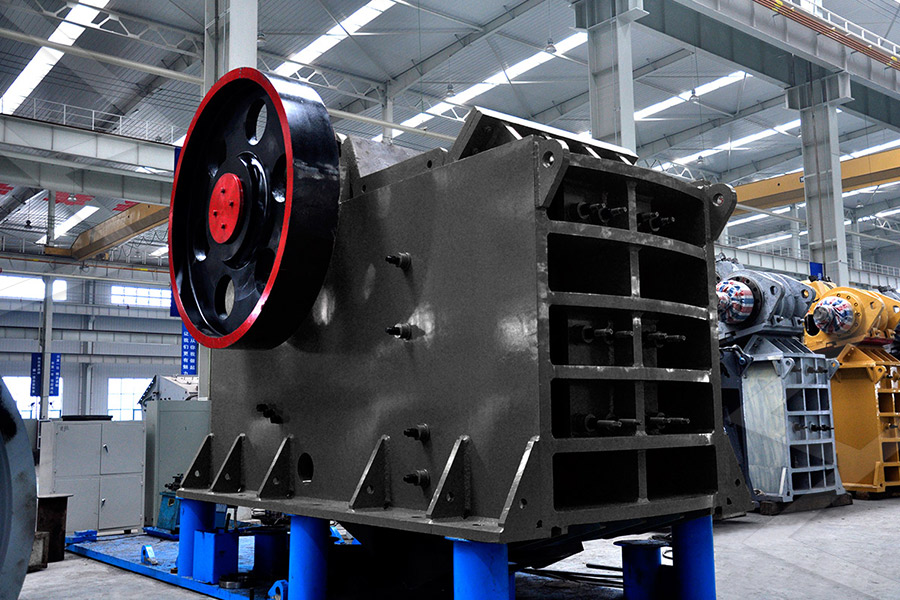

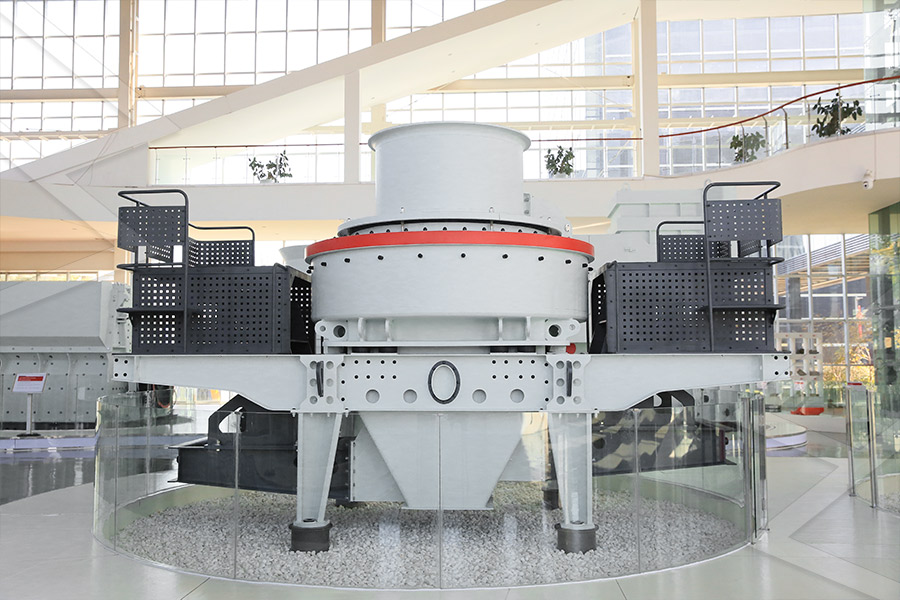

HighQuality Hammer Mill Machine for Sale

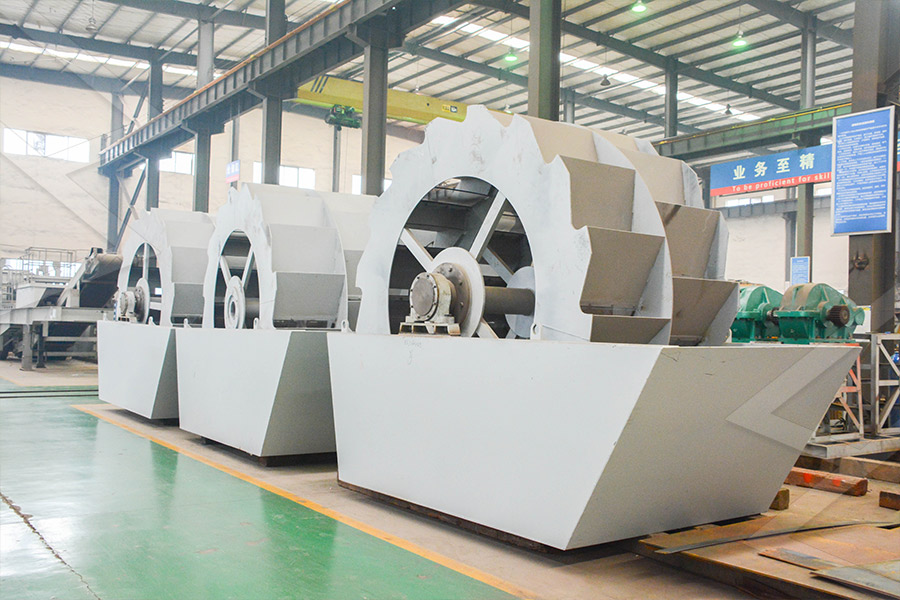

Includes hammer mill, inlet chute, belts, motor, full enclosure guards, all integrated on a steel skid Robust construction with longwearing chrome hammers, AR400 abrasionresistant protective liners and screens Sizes: 16 Hammer mills are versatile machines for material size reduction Applied to ore milling applications, our hammer mills can produce flourfine rock powder Glass pulverizing, rock recycling, porcelain recycling, and similar material reduction Hammer Mills Mt Baker Mining and Metals2024年10月10日 This article focuses on two widely used types: the hammer mill and the jet mill Hammer mills are often used for generalpurpose grinding and the finished product particle size ranges from millimeters to tens of microns The jet mill is primarily used for superfine grinding applications and creates particles sizes down to a few micronsHammer Milling and Jet Milling Fundamentals AIChE2022年12月11日 Hammer mill dengan sistem pemotong adalah jenis hammer mill yang dilengkapi dengan alat pemotong untuk memotong bahan baku menjadi potonganpotongan yang lebih kecil sebelum masuk ke dalam chamber Alat ini biasanya digunakan untuk menghancurkan bahan baku dengan ukuran yang lebih besarHammer Mill: Fungsi, Cara Kerja, Jenis Dan Perawatannya

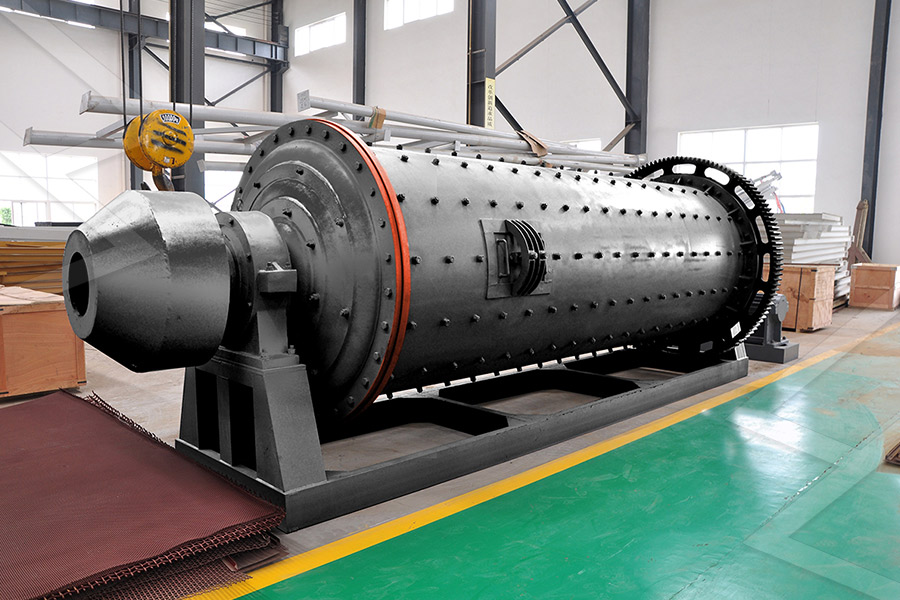

Hammer Mill HM Neuman Esser

The hammer mill, also known as the pulverizer, works according to the principle of impact grinding Its core consists of a rotor with wear resistant impact hammers and external housing for the roller bearing Our hammer mill HM is ideal for grinding, crushing, and processing soft to mediumhard grinding materials such as minerals for China Feather Meal Machine catalog of Top Quality Single Screw Dry Extruder Machine for Feather Powder Processing, High Production Automatic Poultry Chicken Feather Extruding Machine for Animal Feed Processing provided by China manufacturer Henan Yearmega Industry Co, Ltd, page1Feather Meal Machine Henan Yearmega Industry Co, Ltd2018年7月19日 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screenDesign, construction and performance evaluation of a flat screen hammer The Hammer and the Feather, an immersive audio and visual installation, takes its name from the experiment performed on Earth’s moon by US astronaut David Scott, which proved Galileo’s assertion that gravity exerts an equal force on all objects Developed at MIT by technical instructor Christian Frederickson and visual artist and filmmaker Greg King, The Hammer, and the MIT Center for Art, Science Technology The Hammer and the Feather

.jpg)

Feather Mill Crushers Plastic Processing Machinery Plastic

Feather Mill, Model: DK, FM, Introduction : Feather Mill is the pulverizer that is manufactured by our company Because both sides of hammer can be used and the change of rotation direction and speed is easy, only two to three kinds of screen can be used for coarse crushing, medium crushing, and fine crushing It is a multifunction A hammer mill is typically good for grinding softer materials with Mohs hardness ranging from 1 to 5, while a jet mill can grind materials with Mohs hardness as high as 10 High hardness materials become very abrasive; therefore, they are not suitable for highspeed hammer mills In a typical jet mill, grindingBack to Basics Hammer Milling and Jet Milling the hammer mill can be run continuously 2kg of the dry feathers are milled at a time in the milling chamber The hammer mill is operated at 3000 rpm This results in a 100 120kg output of fibrillated fibres per hourWOA1 Process for processing feathersParts for all Meadows hammer mills may be purchased by contacting Meadows Mills directly We are happy to evaluate any product free of charge If you are interested in sending a product for evaluation please contact Brian at 18006262282 or 3368382282Hammer Mills, for All Your Grinding Needs Meadows Mills

.jpg)

Hammer Mills for Material Reduction Williams Patent Crusher

Hammer mills use midair and impact crushing, grinding, and shredding This allows them to handle virtually any material Learn more about each of our hammer mill crushers below and contact the Williams team to discuss your application Our sales engineers can help you find the right machine for the job2021年1月19日 Our paper presents the hammer mill working process optimization problem destined for milling energetic biomass (MiscanthusGiganteus and Salix Viminalis) For the study, functional and constructive (PDF) Optimization Issues of a Hammer Mill Working Process 2024年5月3日 Humans have been pondering this for a while Click on the images below to see how our understanding has changed Now let’s say you’re on the Moon If you were to drop a hammer and a feather Which falls faster a feather or a hammer? BBC Teach2015年11月11日 4 5 Steaming Drying: Steam dryer is used to dry the dewatered feathers at the temperature of 300°F for 90120 mint There are steamed plates inside it where the feathers are dried At the dryer exit temperature moves downward up to 200°F Then cooled at the end 6 Grinding: After drying the hydrolyzed feather is grounded with the general hammer mill 7 Production of feather meal PDF Free Download SlideShare

.jpg)

Hammer Mill Beater: 3 Things You Need to Know JD Ring Die

2023年1月12日 The material of the beater should be chosen based on the type of materials being processed and the intended application of the hammer mill Hard materials like high carbon steel, hardened steel, tool steel, and tungsten carbide are suitable for tough and abrasive materials, while softer materials like stainless steel are more suitable for food processing and The first product Prater (formerly Prater Pulverizer) developed was a hammer mill, also known as hammer forges or hammer works Since that time, our company has sold thousands of hammer mills to customers in various industries For over 90 years, we have relied on advanced technology to properly engineer our mills for new applicationsHammermills Particle Size Reduction Equipment Prater HIPPO Scaffolding for bottom square funnel for hammer mill system Model #: Serial #: Electrical Requirements: (ID#:ER2401112) Roxboro, NC, USA WILLIAMS Hammermill used WILLIAMS hammermill S/N 15958 Top opening approximately 12″ x 18″ 2 1/2″ fixed wide hammer type No motor but base for direct connectionUsed Hammermills for sale Fitzpatrick, Jeffrey AlpineWhat is a Hammer Mill Crusher? A hammer mill is a rock crusher that employs a rain of hammer blows to shatter and disintegrate a variety of materials Hammer mills produce a finished product size that is dependent upon the following Industrial Hammer Mill Crusher Stedman

.jpg)

Hammer Mills The CS Bell Co

2024年2月12日 We offer our hammer mills in three standard widths: Model 10 (6"), Model 20 (9"), Model 30 (12"), in both blower and bottom discharge designs Click here for details on our standard hammer mill package OR click here for the wide variety of options we offer We modify our current models for specialized applications, such as: 2020年9月29日 The hammer mill machine was evaluated under three levels of different drum speeds of 2600, 3300 and 4000 rpm, four different sieve hole diameters of 3, 6, 12 and 18 mm, three different number of DEVELOPMENT AND PERFORMANCE EVALUATION OF HAMMER MILL 2020年12月15日 A hammer mill is a machine that uses a crushing technique to grinding solid food products that need to be broken down into suitable forms They are highly effective at grinding the solids without making too much noise, and as for pharmaceutical processes, there’s also minimal heat buildup This equipment is made in standardised as well as What Is a Hammer Mill and Where Can You Use It?Our Corn Hammer Mill offers exceptional quality and style within the Feed Processing Machinery categoryModern feed processing machinery utilizes advanced technologies such as grinding, mixing, extrusion, and pelleting to create highquality feed products efficiently These technologies help enhance productivity and meet diverse processing Corn Hammer Mill MadeinChina

Indicators of Nutritional Value of Hydrolyzed Feather Meal

2019年3月13日 Indicators of Nutritional Value of Hydrolyzed Feather Meal1 J S Moritz* and J D Latshaw*,2 Department of Animal Sciences, The Ohio State University, Columbus, Ohio 43210 friable product was then ground in a hammer mill containing a 03175cm screen The complete meals were stored in a cold room at −29 C until needed for testing Two 2024年8月18日 A portable hammer mill offers an affordable, userfriendly solution for domestic milling, similar to household blenders and appliances 2 Materials and Methods 21 Description of the Hammer Mill The hammer mill for domestic use was developed at the Department of Agricultural and BioEnvironmental Engineering, The Federal Polytechnic, AdoDesign and Fabrication of a Hammer Mill for Domestic For decades, Jacobs has been manufacturing quality, longwearing hammer mill hammers Our hammers are formed from a special steel alloy Hammers are machined, hardfaced, and heat treated to match user requirements Hammer Mill Replacement Parts Wear Parts Jacobs GlobalDesign of NEUE HERBOLD hammer mills The NEUE HERBOLD hammer mills series HM are equipped with robust and highly wearresistant tools (hammers, blow bars) The outside housed in pedestal bearings rotor shaft is separated from the grinding chamber Through the solid steel weldment the hammer mill is very resilient and holds enormous loadsHammer Mills Neue Herbold GmbH

.jpg)

Hammermills Hammer Mills High Capacity

4 天之前 Powerful and efficient hammermills engineered for highspeed, highvolume grinding to achieve fine particle sizes With a broad range of throat widths from 20” to 76” and large diameter hammer circles, these robust mills boast 2023年11月29日 Abstract The efficiency of a hammer mill with combined methods for suspending hammers by the rotor was estimated under the production conditions of the fractional preparation of fluxes in the agglomeration shop of branch No 1 of the Alchevsk Metallurgical Plant (Southern Mining and Smelting Enterprise) Tests of a DMRiE 145 × 13 hammer mill Estimating the Efficiency of a Hammer Mill with Combined 2 天之前 Each hammer mill unit is supplied with 4 screens + blank screen for chipping 1st Screen is 08mm for fines; 2nd Screen is 30mm for fine broken grain; 3rd Screen is 50mm for broken grain; 4th Screen is 120mm for coarse Hammer Mill + Chipper + Grinder All in One HAZEMAG hammer mills are eminently suited to the combined drying grinding of various materials In this process, hot gases are passed through the hammer mill simultaneously with the comminution of the material Thanks to the large surface area created by the crushing process, a very high evaporation rate is achieved, the combination of the Hammer Mills HAZEMAG

Hammer mills PrallTec

The mill housing of the hammer mill is made in a sophisticated welded construction with two hinged parts, which can be opened hydraulically The interior is armored in the wear zones with wearresistant Hardox sheets or castings, and the rotor disks are also made of a wearresistant material suitable for hammer millsThe rugged RETSCH Hammer Mill HM 200 accepts large feed sizes up to 100 mm which can be reduced to less than 08 mm, depending on the sample properties The mill is ideally suited for processing large volumes batchwise or continuously which ensures high sample throughput Thanks to features like rugged design, easy handling and quick cleaning Hammer Mill HM 200: For Laboratory Pilot Plant RETSCHInventing this technology is one more feather to our cap and a total grinding solution for all types of grinding "QuickGapAdjustment" QGA, as its name implies this technology is a boon for grinding different sizes of products as fine/ Medium/ coarse by quick change of gap between hammer tip and screen, thus creating ideal parameters for Full Screen Hammer Mill Manufacturer India Lark EngineeringBuy the best quality hammer mills for mining business, all sizes available Show Hammer DMH01PC24XR Rated 0 out of 5 $ 3,86000 Add to cart Hammer DMGG02Changfa Rated 0 out of 5 $ 1,80000 Add to cart Hammer DMH03Changfa6Beater Rated 0 out of 5 $ 1,30000 Add to cart Hammer DMH04Changfa8Beater Rated 0 Hammer Mills Daws Plant Machinery Zimbabwe

Metal recycling machine – Hammer mills FOR REC SPA

The hammer mills are extremely powerful and fast in processing, allowing the grinding of heterogeneous materials Hammers mill Z16 Hammer mills designed for crushing a wide range of materials, efficiently reducing the final product into small, uniform fragments Views video Hammers Mills2018年9月22日 The compost pile had reduced in its size No intact feathers were seen Feather rachis, which had not got completely degraded, had turned brittle The compost had a fresh pleasant smell typical of rich fertile soil The dark brown compost was dried and pulverized to particles of uniform size (Fig 4) using hammer mill pulverizerProduction of HighQuality Compost from Feather Waste: A