Roller Mill In Cement Plants Pi滑石 Venezuela

.jpg)

New INVECEM plant in Venezuela orders two roller mills

2015年4月9日 Venezuela: AVIC International Beijing Co Ltd and its customer Industria Venezolana del Cemento (INVECEM) have ordered two vertical roller mills for INVECEM's 6 天之前 The LM 484 LOESCHE vertical roller grinding mill will grind cement raw material with a capacity of 280t an hour at 12% R 009mm in the plant in Monay The LM 533+3C cement mill LOESCHE Delivers Further Vertical Roller Grinding Mills for 2017年6月19日 Today's cement plants can now be designed with the onemill concept for both raw material and cement grinding The advantages of the modular vertical roller mill Grinding process optimization IEEE Xplore2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Operational parameters affecting the vertical roller mill

Introducing the Vertical Roller Mill with Driven Rollers: An

2015年8月31日 With the market demand for efficient, highly flexible, and highcapacity plants for cement production, it was time to develop an innovative drive concept to cope with the 2022年4月4日 The quadropol® vertical roller mill by thyssenkrupp Industrial Solutions takes a holistic approach to modern grinding systems in terms of its simple and compatible design VERTICAL ROLLER MILLS A holistic VRM approach2021年1月1日 For the past three decades the vertical roller mill has emerged to be the preferred choice for grinding raw materials With the grinding capacity of a vertical roller mill and the Review on vertical roller mill in cement industry its The newly developed modular roller mill for grinding cement raw material, cement clinker, and additives with an installed power of up to 12,000 kW was specifically designed to meet those The latest innovative technology for vertical roller mills:

.jpg)

Industria Venezolana del Cemento Cement industry news from Global Cement

2015年4月9日 Venezuela: AVIC International Beijing Co Ltd and its customer Industria Venezolana del Cemento (INVECEM) have ordered two vertical roller mills for INVECEM's 2024年10月13日 The adoption of vertical roller mills in the cement industry has led to significant improvements in grinding efficiency and operational performance With their energysaving Vertical roller mills enhance grinding efficiency in the cement The use of vertical roller mills in cement plants offers numerous benefits that cannot be overlooked This technology offers higher efficiency, better energy savings, and better performance than traditional ball mills Vertical roller mills have a smaller footprint, are more compact, and easier to install, making them ideal for smaller and Vertical Roller Mill in Cement Plant ball mills supplierThe most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for Coal Mill in Cement Plant Vertical Roller Mill

.jpg)

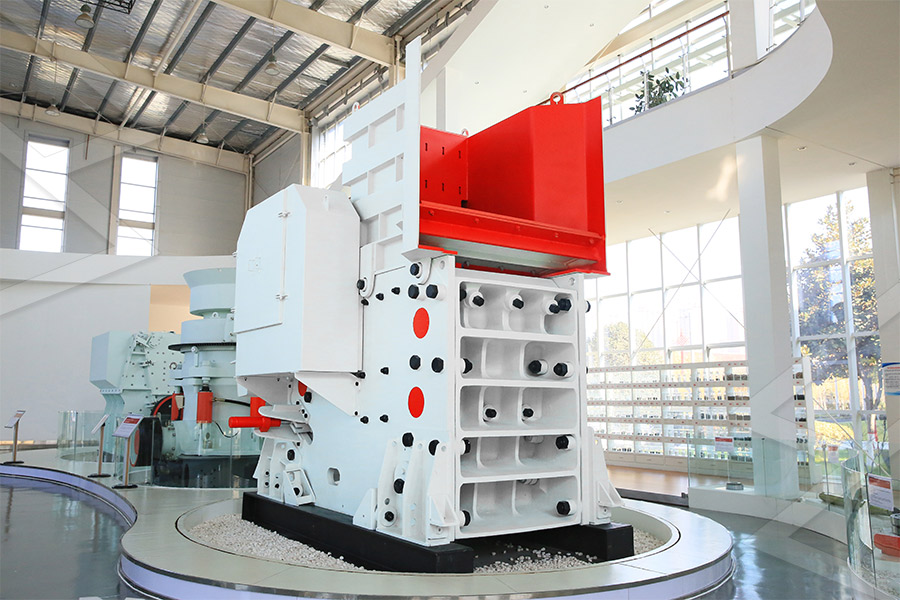

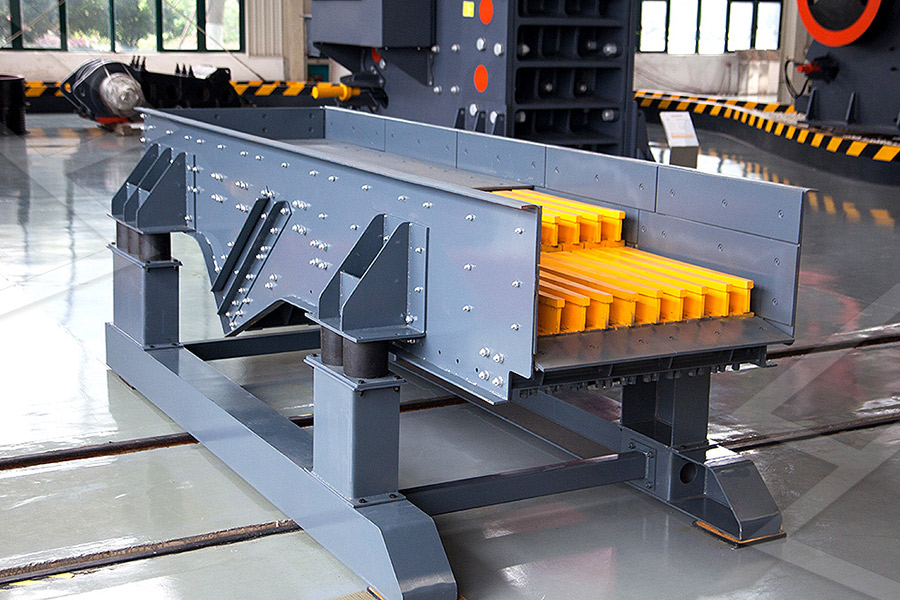

Hydraulic Roller Press in Cement Plants AGICO

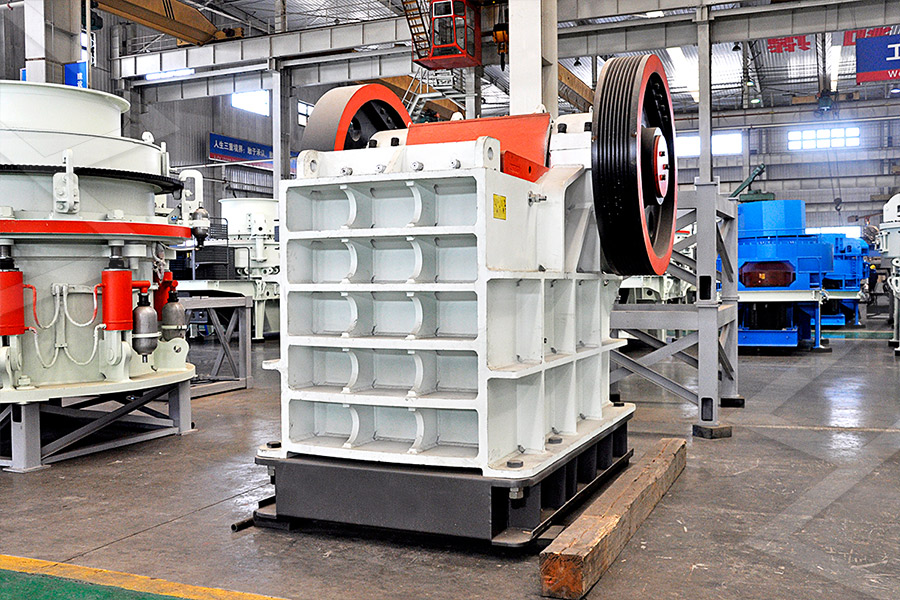

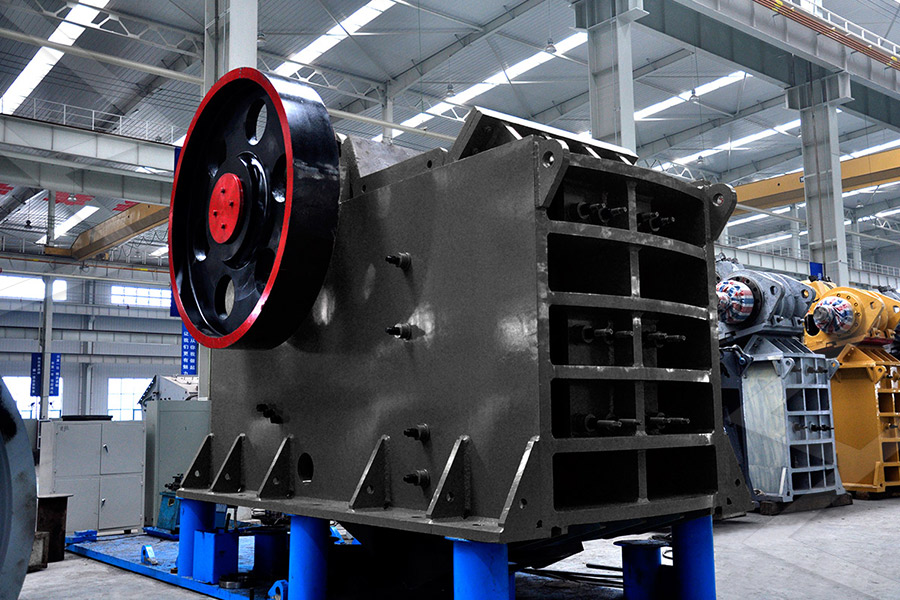

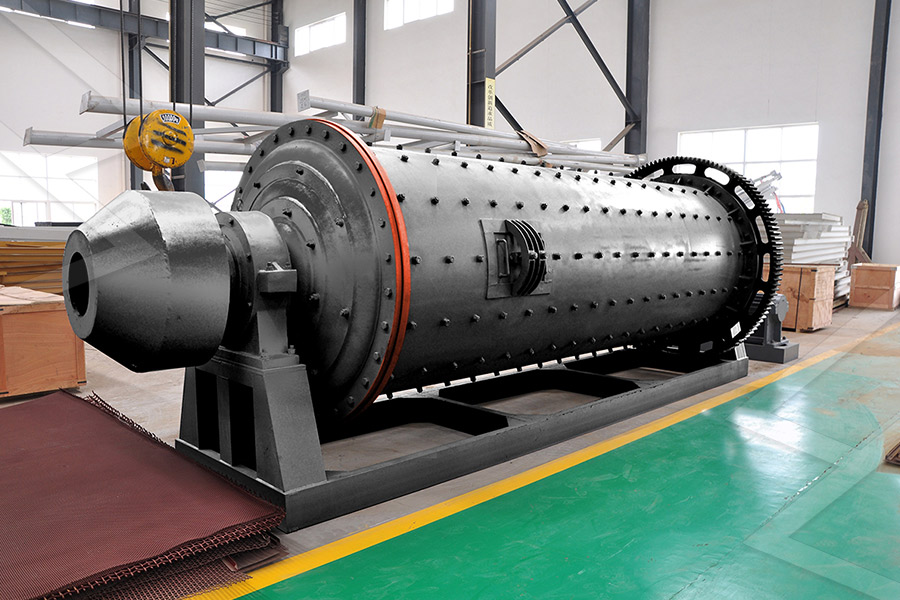

The cement roller press is a type of material crushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and Of course, even if we set a more appropriate cement fineness, it is difficult to change the current situation that the flow velocity in the opencircuit ball mill is only 1/21/3 of that in the closedcircuit ball mill with the same specification, which will lead to poor comprehensive performance of finished cement, low system output and Ball Mill In Cement Plant Cement Ball Mill AGICO CementThe choice between a vertical roller mill and a ball mill for cement grinding ultimately depends on the specific needs and constraints of the cement plant VRMs offer significant energy savings, finer product control, and reduced maintenance costs, making them an attractive option for modern cement plants focused on efficiency and sustainabilityVertical roller mill vs ball mill for cement grinding: 2024年1月3日 studies were performed at vertical roller mill of ESCH Cement Plant, which is located in Luxemburg Performance evaluation results of vertical roller mill in cement grinding application are Performance Evaluation of Vertical Roller Mill in Cement

VRM In Cement Plant Maximize Energy Saving CNBM

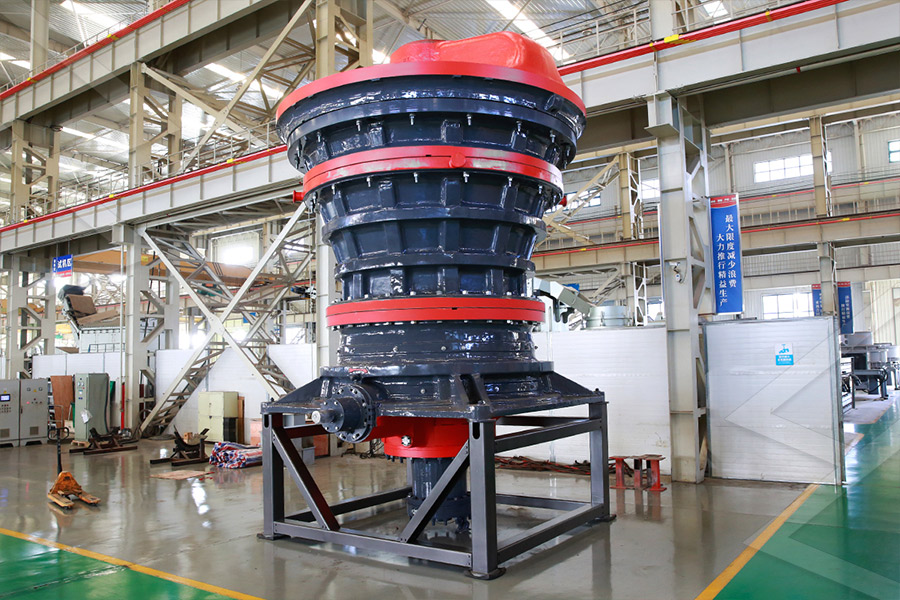

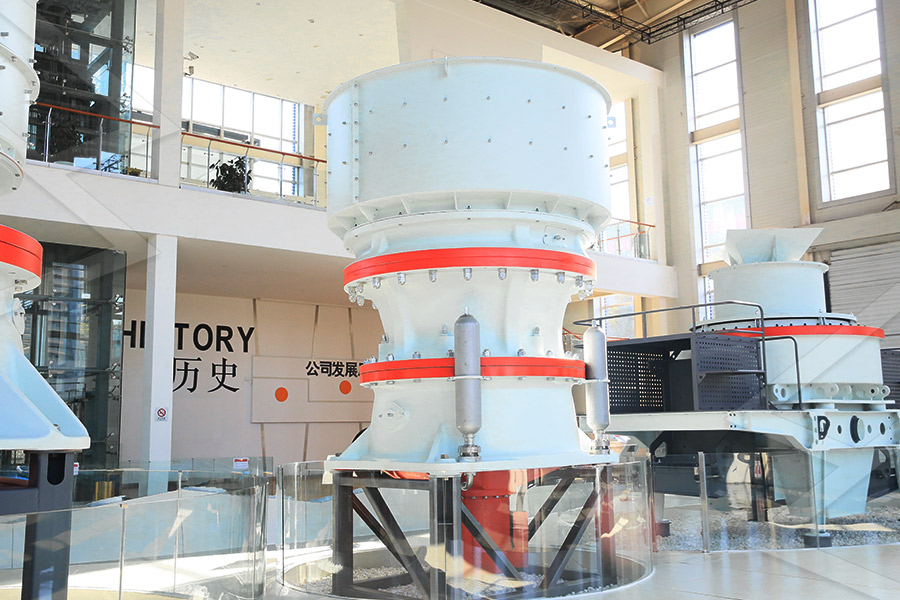

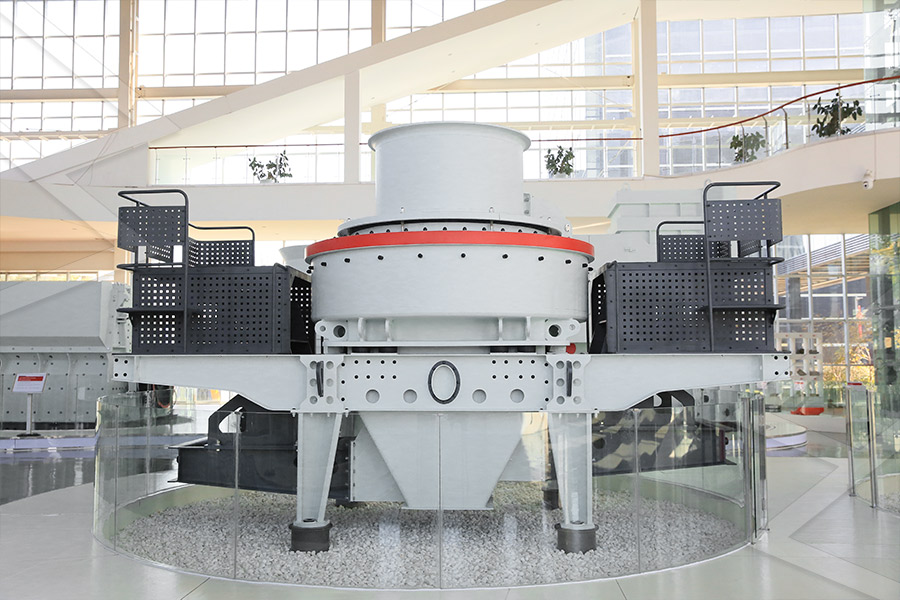

Vertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy 2023年10月25日 Cement production has always been an integral part of the construction industry, and the cement vertical roller mill plays a key role in this process Vertical roller mills crush raw materials by applying pressure between a pair of rollers, which helps reduce the gaps between materials and makes the powder more uniform and denseWhat Is The Largest Cement Vertical Roller MillFor cement plant applications that require even better results, our customdesigned solution, Expand+, will offer even more favorable results Vertical Roller Mill Cement Plant Parts From a Firm With Global Reach Magotteaux is wellknown for vertical roller mill expertise in cement plants all over the world We have over 200 technical sales Vertical Roller Mill Cement Plant MagotteauxThe cement roller press is a type of materialcrushing machine which is often used in cement plants It usually works together with a ball mill to form a pregrinding or finalgrinding system for the grinding of raw materials, coal, and clinker Compared with the traditional tube mill and ball mill, the roller press has lower energy consumption and higher production efficiency, Hydraulic Roller Press in Cement Plants AGICO Cement

.jpg)

Raw Mill, Cement Raw Mill, Raw Mill In Cement

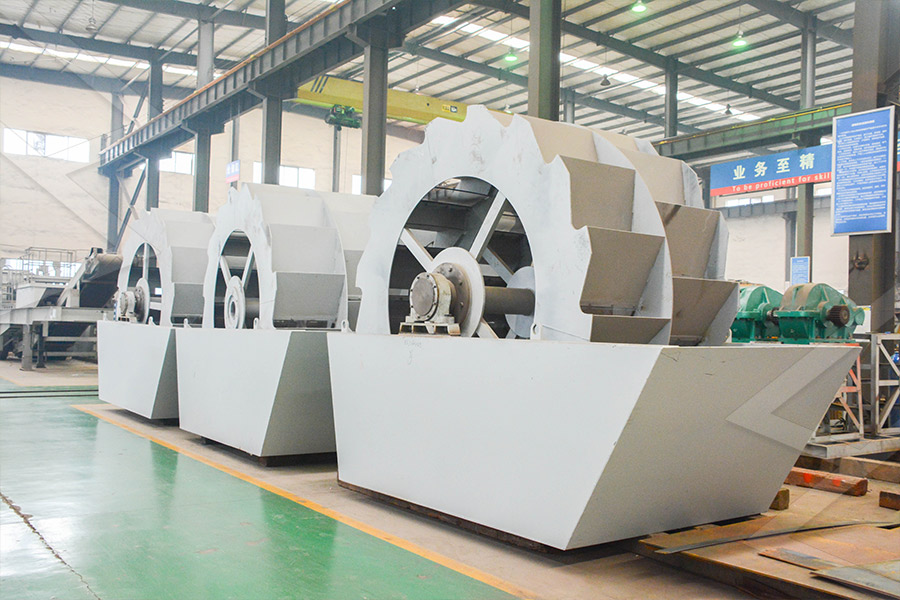

Raw mill is generally called cement raw mill, raw mill in cement plant, it refers to a common type of cement equipment in the cement plantIn the cement manufacturing process, raw mill in cement plant grind cement raw materials Airswept coal mill is the main equipment of cement plant, also called coal mill in cement plant, used for grinding and drying various hardness of coal, crushing the coal briquette into pulverized coalIt is the important auxiliary equipment of Coal Mill In Cement Plant, Airswept Coal MillTypes of cement mills There are basically 4 types of cement mills in use today: Ball Mill (BM) Ball Mill (BM): predominant despite higher energy consumption partly because of historical reason but partly also because it still offers Improvements in New Existing Cement 2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality How Does a Raw Mill Work in a Cement Industry

.jpg)

Expert Cement Grinding Solutions from AGICO AGICO Cement Plant

According to different grinding systems, the oftenused cement mills include ball mill, roller press, and vertical roller mill In addition to the cement mill, other commonly used equipments in the cement grinding station include cement mill separators , bag filters and ESPs , cement silos , conveyors , bucket elevators, cement roto packers , etcAGICO Cement Vertical Mill AGICO Cement Ball Mill Cement Vertical Mill Grinding System Cement vertical mill, also called roller mill, is another raw mill commonly used in cement pared with the cement ball mill, it has a great difference in structure, grinding principle, process layout, automatic control, and energy consumption, which play an important role in the Raw Mill – Raw Mill In Cement Plant AGICO Cement Raw MillAGICO vertical roller mills can be used as cement mills, raw mills, and slag mills AGICO also supplies vertical roller mill components and parts, we can customize machines according to customers’ needs Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish []Vertical Roller Mill for Sale AGICO Cement PlantVertical raw mill is one kind of raw mill, generally used to grind bulk, granular, and powder raw materials into required cement raw meal in the cement manufacturing plantVertical raw mill is an ideal grinding mill that crushing, drying, grinding, grading transfer set in one It can be widely used in cement, electric power, metallurgy, chemical industry, nonmetallic ore, and other industriesVertical Raw Mill Cement Raw Mill Raw Mill In Cement Plant

.jpg)

Vertical Roller Mill for Sale AGICO Cement Plant

Vertical roller mills (VRM) are a type of mainstream clinker grinding equipment in the cement manufacturing process Vertical roller mills are still newish cement mills since their history in cement production is no more than 20 years, but they have already become the standard cement equipment in many regions and are getting more and more popular among cement producers2024年1月1日 It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it had been widely used in various metal and nonmetallic minerals such as iron ore, manganese ore, cement raw clinker, limestone, blast furnace slag, and coal The highpressure roller mill mainly consists of the Roller Mill SpringerLink2020年8月13日 The mill consists of the lower casing, upper casing, table mounted on the vertical planetary gear reducer and grinding rollers supported by the swing levers The separator is installed at the upper parts of the mill The raw material fed through the air lock gate is ground between the rollers and table with the grinding force added byVERTICAL ROLLER MILLS AMCLThe numerous positive experiences with Loesche mills, the competitive price and the fast delivery time of only seven months were decisive factors in Sinoma’s decision to again choose the grinding plants of the vertical roller mill Loesche supplies four vertical roller mills (VRM)

.jpg)

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production process The standard coal consumed by the new dry process for producing 1 ton of cement clinker is usually between 100 kg and 130 kg, and the fuel cost accounts for Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball MillDownload scientific diagram Schematic of raw vertical roller mill circuit in the Ilam cement plant from publication: Modeling of energy consumption factors for an industrial cement vertical Schematic of raw vertical roller mill circuit in the Ilam cement plant Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills that satisfy the cement user’s demandsNevertheless, the two types of mills have their distinctive meritsCement grinding Vertical roller mills VS ball mills

.jpg)

Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]The fastest growing export markets for Cement of Venezuela between 2021 and 2022 were Colombia ($508M), Brazil ($442k), and Guyana ($215k) Imports In 2022, Venezuela imported $745M in Cement, becoming the 138th largest importer of Cement in the world At the same year, Cement was the 217th most imported product in VenezuelaCement in Venezuela The Observatory of Economic 2024年5月23日 The belt conveyor in cement plant systems provides an efficient and seamless method for transporting materials across various stages of production From handling raw materials like limestone and clay to moving clinker and cement to storage, the belt conveyor in cement plant settings ensures that every phase of cement processing runs smoothly Optimizing Material Flow with Belt Conveyor in Cement Plant2024年10月28日 CEMENT 4 SikaGrind® FOR VERTICAL ROLLER MILLS Pilot Mill (Picture: Loesche GmbH, Germany) The production of Portland Cement (OPC, CEM I) with Vertical Roller Mills can demand the following benefits from a Grinding Aid: ́ Increased production rate, energy saving ́ Higher fineness, faster strength development ́ Reduced vibration, less wearSikaGrind® for vertical roller mills

.jpg)

(PDF) The latest innovative technology for vertical roller mills

2014年4月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on @article{Ghalandari2021ACS, title={A case study on energy and exergy analyses for an industrialscale vertical roller mill assisted grinding in cement plant}, author={Vahab Ghalandari and Mohamad Esmaeilpour and Naser Payvar and M Toufiq Reza}, journal={Advanced Powder Technology}, year={2021}, volume={32}, pages={480491}, url={https://api A case study on energy and exergy analyses for an industrial 2021年1月6日 The grinding process of cement in a vertical roller mill over ball mills is optimized by the authors of [21] in order to minimize power consumption The energy consumption is also studied in semi Review on vertical roller mill in cement industry its Cement mills are the milling machines used in cement plants to grind hard clinker into fine cement powders Cement ball mill and vertical roller mill are two most widely used cement mills in today’s cement grinding plants and are also the main types of cement mill we produce As a professional cement equipment manufacturer, AGICO has rich experience in the designing and Cement Mill for Sale Buy Cement Ball Mill Vertical Roller Mill

.jpg)

Grinding Roller For Vertical Roller Mill AGICO Cement Plant

AGICO Cement manufactures grinding rollers for vertical roller mill according to the requirements of customers The grinding roller is the vital grinding component of vertical roller mill Because the grinding roller can directly exert force on the material, the grinding roller has high requirements for hardness and wear resistance in actual 2020年11月5日 As you all know, the process of a cement manufacturing plant can be divided into several steps, including crushing, raw milling, clinker calcining, cement milling (or cement grinding), packing and etc In the complete cement production line, the cement mill process plays a very important role The design of cement milling and cement mill process will produce a Ball Mill, Vertical Roller Mill Cement Plant2015年4月9日 Venezuela: AVIC International Beijing Co Ltd and its customer Industria Venezolana del Cemento (INVECEM) have ordered two vertical roller mills for INVECEM's new cement plant in Monay, Trujillo, Venezuela The order comprises a LM 533+3C for grinding clinker and an LM 484 raw meal mill The new cement plant is a joint venture project of the Industria Venezolana del Cemento Cement industry news from Global Cement2016年10月5日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equip‐ ments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study per‐ formed on a EnergyEfficient Technologies in Cement Grinding

EVALUASI KINERJA VERTICAL ROLLER MILL (Cement

1999年4月18日 plant 2, namely the Vertical Cement Mill (VCM) VCM itself works for mixing and refining clinker with corrective materials to become cement, besides that this2024年3月19日 EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill) PT SEMEN BATURAJA (Persero) Tbk RIO RISKI SIMBOLON, RAKHMAT ADIWIJAYA, SAFARUDDIN Universitas Lampung rio2016riski@gmail rakhmatadiwijaya EVALUASI KINERJA VERTICAL ROLLER MILL (Cement Mill)