What Is Mean By Transfer Tower In Conveyor Belts

.jpg)

Conveyor Structure Transfer Towers 7systemsco

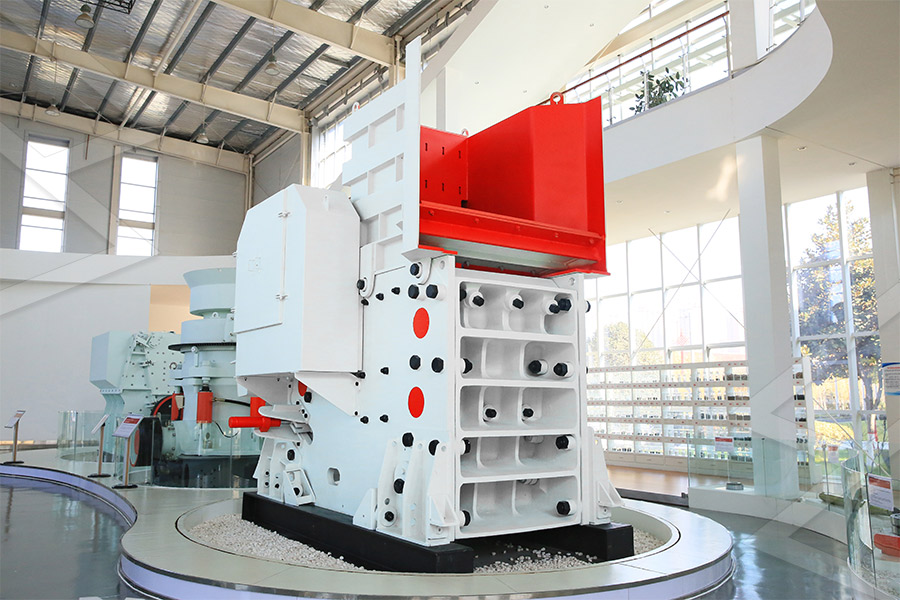

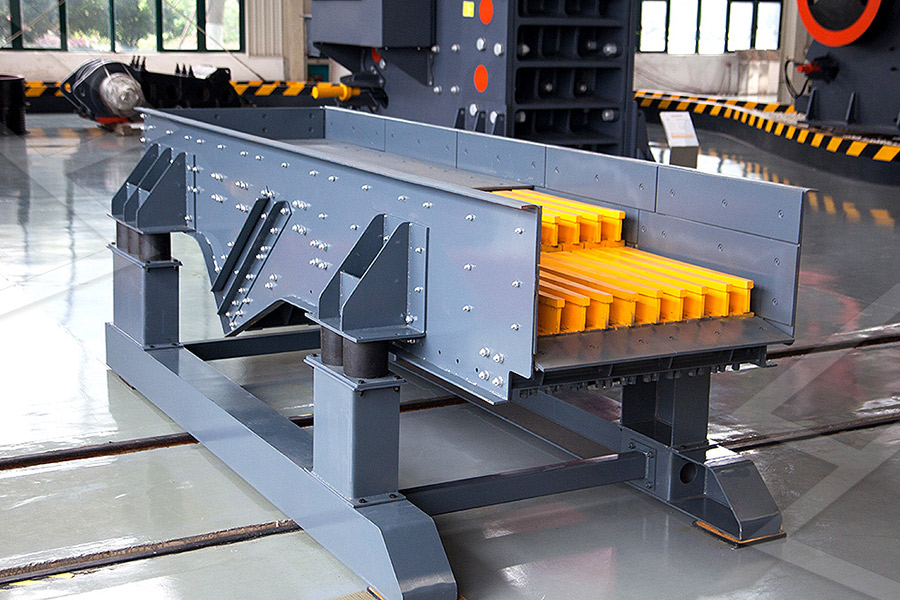

What Are Transfer Towers? Transfer towers are crucial components in conveyor systems, providing a transition point where materials are transferred from one conveyor belt to another These structures are designed to handle various Download scientific diagram Transfer tower house from publication: Cost and Quantity Comparative of DLCS and PCS Tower Structures in Conveyor Belt Systems This research paper focuses on the Transfer tower house Download Scientific 2019年3月25日 Advances in conveyor Technology Straight belt conveyors can convey unbroken over long straight distances, but require costly transfer towers to change direction Each time a Advances in Conveyor technology BEUMER Group2023年11月6日 The objective of the paper is to assess the economy and safety of transfer tower structures by exploring double layer conveyor system (DLCS), parallel conveyor system (PCS)Cost and Quantity Comparative of DLCS and PCS

Belt Conveyor an overview ScienceDirect Topics

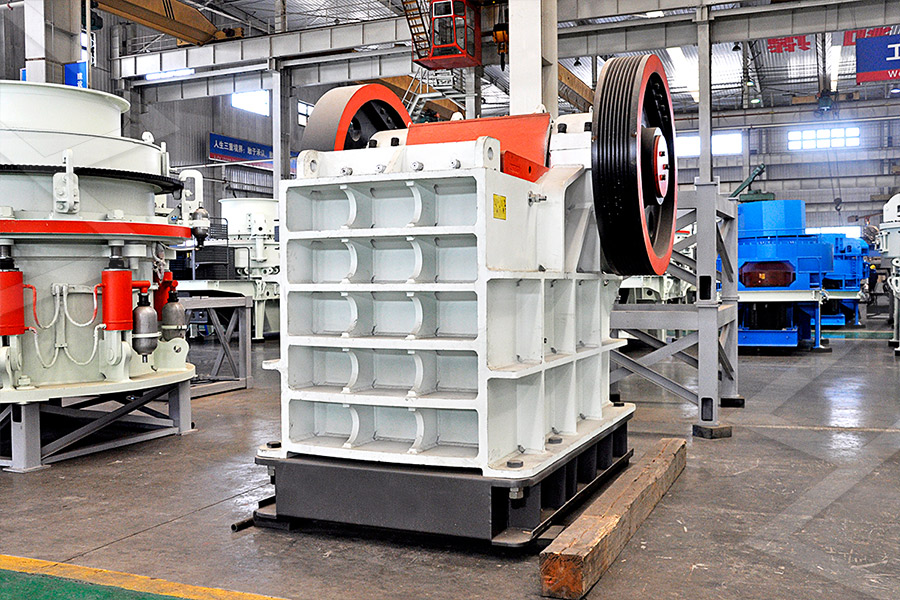

design and engineering of belt conveyors must be directed toward keeping the belt in operating condition 3 the belt transfer points should be reduced to a minimum to cut degradation, dust, The performance of conveyor transfer chutes is an essential part of the productivity of conveyor belt systems in the bulk solids industry Engineered Transfer Points (conveyor Transfer Points) design fabrication and installations Conveyor Transfer Chutes Engineered Transfer 2024年10月24日 Efficient material handling in conveyor systems hinges on effective belttobelt transfers Whether materials are moving between conveyors within the same system or transitioning to different processes, the method of Optimizing BelttoBelt Transfers: Strategies for Industrial Chains Belts » Mumbai » Packing Belt Conveyor in Mumbai;COBIT Belt Conveyors are reliable meantransfer tower belt conveyor diebold bautransfer tower belt conveyor what is mean by transfer tower in conveyor beltsmd

.jpg)

Tips Tricks For Conveyor Transfer Chute Design Martin Eng

2024年10月24日 Tips Tricks For Conveyor Transfer Chute Design Key Considerations for Efficient Conveyor Chute Design Head Chute Design The dimensions of the head (discharge) 2024年5月3日 In the realm of belt conveyor chute design, the Chute Design Handbook PDF and Transfer Chute Design Manual PDF serve as indispensable resources for engineers and operatorsThese documents offer comprehensive Belt Conveyor Chute Design: How to Design and 2023年3月13日 Conveyor belts resemble a band or loop of rollers connected to rotors powered by a motor The belts can be as narrow as one inch (25 mm) or as wide as five feet (15 m), with plastic modular belts as wide as ten feet (3 m) Conveyor belts are made of highly durable and sturdy materials, much like heavyduty machineryConveyor Belts: What Is It? How Does It Work? Types, Parts2023年2月16日 Belt Conveyors is a system that is designed to transfer or transport physical items such as materials, goods, and even people from one location to another One of the most popular types of conveyors is the flat Belt Conveyors Components, Types, Design, and

.jpg)

What Is EP in Conveyor Belt: Advantages and Specifications

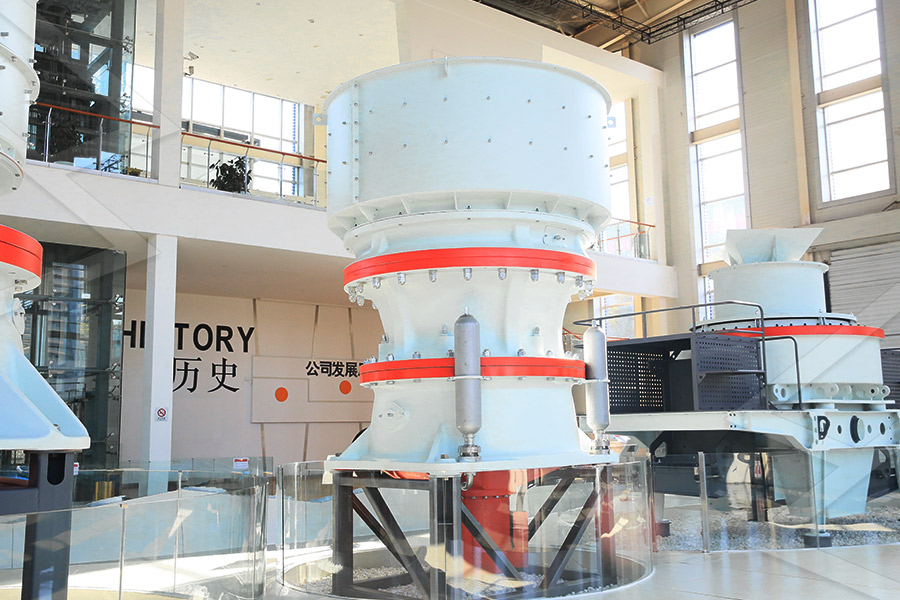

2024年5月23日 What is EP in Conveyor Belt EP in conveyor belts stands for “PolyesterNylon,” which refers to the type of fabric used in the construction of the belt This fabric is composed of polyester fibers in the warp (longitudinal) direction and nylon fibers in the weft (transverse) direction, combining to create a robust material that optimizes performance in demanding Conveyor belts resemble a band or loop of rollers connected to rotors powered by a motor The belts can be as narrow as one inch (25 mm) or as wide as five feet (15 m), with plastic modular belts as wide as ten feet (3 m) Conveyor belts are made of highly durable and sturdy materials, much like heavyduty machineryConveyor Belts: What Is It? How Does It Work? Types, Parts2024年3月11日 This section will provide an understanding of how transfer towers integrate with conveyor belt systems and delve into the latest innovations in conveyor belt chute technology The Fusion of Transfer Towers and Conveyor Belt Chutes Transfer towers serve as a crucial link in any material handling process involving a conveyor belt systemConveyor Belt Chutes Manage and Redirect Material Flow2024年3月18日 to the existing stockpile feed conveyor adjacent to the concentrator There are four conveyors including the crusher discharge conveyor and three transfer towers These include a 2,800 mm wide, 80 m long discharge conveyor and transfer tower; an 1,830 mm wide and 410 m long sacrificial conveyor and transfer tower poweredCONVEYORS ABB

.jpg)

Portable Transfer Conveyors West River Conveyors

5 天之前 Our tough fabricated backbones and materialspecific belts mean our portable conveyors can handle anything you or your existing handling equipment can throw at it, including: Terminal equipment is the engine of every conveyor For more than 40 years, West River Conveyors has been building robust, balanced terminal systems to power our world 2021年10月24日 A driving mechanism such as an electric motor rotates the pulleys, which moves the belt across the conveyor length The belt’s speed can be fixed or variable, depending upon the application required Figure 3 A belt conveyor Image used courtesy of Ultimation Inc A conveyor belt is commonly used and is a generally less expensive optionIntroduction to Conveyor Belt Systems Technical Articles2021年1月26日 V = Belt speed (m/s) A = Conveyor’s belt crosssectional area Belt speed should be specified such that it does not cause spillage of the raw material being conveyed Suitable conveyor belt speed typically ranges between 25 m/s and 35 m/s Higher belt speed usually translates to a higher horsepower requirementMaterials conveyors: A guide for specifying belt conveyor systems2024年6月9日 The conveyor belt definition encompasses a moving strip of material, often rubber or metal, used in various industries to transport goods efficiently Conveyor belts play a crucial role in manufacturing, mining, Detailed Conveyor Belt Definition and Its

.jpg)

Tripper Conveyor System Small Footprint But

2024年6月9日 A tripper conveyor system is a type of conveyor belt used in construction, mining, and other large earthmoving projects A tripper conveyor system is a specialized material handling mechanism used to distribute bulk Conveyor Belt Materials are a critical component of conveyor systems, playing a crucial role in the efficient movement of materials Ideal for applications requiring precise positioning and small product transfer; Modular Plastic Belts: Modular plastic belts are made of interlocking plastic modules, offering versatility and customization Conveyor Belt Materials: Types Varieties a complete guideA conveyor belt is the carrying medium of a belt conveyor system, one of the many types of conveyor systems available today Each conveyor system requires different modules in order to function properly and do the tasks required by the belts The different tasks can range depending on the weight required, the speed required, and the throughput of products on the conveyor What is a Conveyor Belt LAC Logistics Automation2024年3月19日 A belt conveyor system, designed to transport materials, goods, or people from one point to another, typically consists of a flat beltdriven mechanism and two motorized pulleys with the conveyor material looped over them, ensuring proper belt tension providing a reliable and efficient means of transporting goods and materials across Conveyor Belt System Design: Best Practices, Types, and

.jpg)

What is a Belt Conveyor? Spaceguard Ltd

How do they work? Conveyor belts consist of a continuous loop of belt wrapped around and driven by one or more pulleys (known as drums) and powered by an electric motor A metal plate bed or rollers normally support the belt from the underside The pulley that is powered is called the drive pulley, whilst the unpowered is known as an idler pulley2024年1月20日 Conveyor belt tensile strength is particularly important in industries where belts are subjected to heavy loads, abrasive materials, and continuous operation A belt with inadequate tensile strength can lead to frequent breakdowns, increased maintenance costs, and significant downtime, all of which negatively impact operational efficiency What is Conveyor Belt Tensile Strength? The Calculation 2020年10月5日 Wagesaving: conveyors replace human labor, which means you won’t need to pay staff to do the job that a conveyor belt will now perform in your business Stresssaving: finally, with a conveyor system set up, it’ll run automatically and diligently for months and years into the future – saving you stressWhat is a Conveyor? Fluent Conveyors2024年6月18日 What is Conveyor Belt Ply Conveyor belts are essential components in numerous industries, from mining to manufacturing, ensuring efficient material transport A critical aspect of conveyor belt construction is the ply Conveyor belt ply refers to the layers of fabric or material that are bonded together to form a conveyor belt and resist ply separationWhat is Conveyor Belt Ply and Conveyor Belt Ply Adhesion

Belt Conveyors MOTRIDAL Bulk Material Handling

2024年10月25日 Each belt conveyor is designed in compliance with the most advanced and uptodate international technical standards (CEMA, ISO) (bridges or galleries), with transfer towers to manage the exchange points DUSTTIGHT BELT CONVEYORS The process is automatically monitored and managed by means of a dedicated control logicThe performance of conveyor transfer chutes is an essential part of the productivity of conveyor belt systems in the bulk solids industry Engineered Transfer Points (conveyor Transfer Points) design fabrication and installations Conveyor Transfer Chutes Engineered Transfer Download scientific diagram Transfer tower house from publication: Cost and Quantity Comparative of DLCS and PCS Tower Structures in Conveyor Belt Systems This research paper focuses on the Transfer tower house Download Scientific 2024年1月16日 Conveyor belts with roller beds are frequently used in airport luggage handling systems and postal sorting facilities Image source 2 Flat Belt Conveyors One of the most widely used conveyor systems in existence today What Is a Conveyor System and What Are Its

.jpg)

Advances in Conveyor technology BEUMER Group

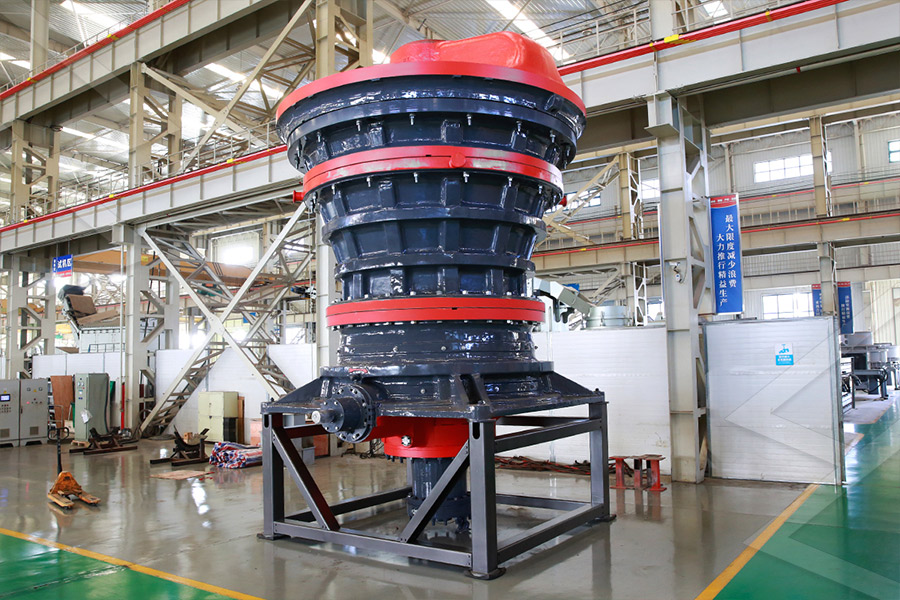

2019年3月25日 many factors and many different types of conveyors But still, the elimination of transfer towers is a prime goal of any design For overland conveyors the distance has to be greater to enjoy the benefits Sometimes in plant conveyors must include multiple transfer points Belt conveyors providing interplant transfer2024年10月24日 Technologies used in baggage handling systems Modern baggage handling systems can generally be categorised into three systems: Conveyor technology – which is the low to mediumspeed transportation of ‘loose’ luggage on a conveyor belt; Tilttray loop technology – which is a highspeed baggage sortation system to handle baggage items of various shapes How does a baggage handling system work? BEUMER Group2024年5月11日 Comprehensive Guide to Safety Devices in Conveyor Belt: PDF Accessibility and Content Accessibility and Benefits of Safety Information The availability of PDF guides that detail safety devices in conveyor belts is invaluable for ensuring workplace safety across numerous industries These guides provide immediate and easy access to critical safety Essential Safety Features for Safety Devices in Conveyor Belt2024年5月13日 The operation of a conveyor belt involves several key components: 1 Motor drive The heart of a conveyor belt system is the motor drive, which provides the necessary power to turn the drive pulley This motor can vary in size and power depending on the load it needs to move and the speed at which the belt must operateHow Do Conveyor Belts Work: A Guide to Conveyors

.jpg)

What Is Conveyor System? Working, And Types The

Can be loaded from any place along the belt; Disadvantages: The simplicity means very limited features; Belt can be difficult to clean and generally does not leave a very successful result; Sticky material can get stuck on the belt and transfer to the return side, the rolls, idlers and pulleys; 2 Gravity Roller Conveyors2024年10月3日 min 300 x d for fabric belts and min 600 x d for steel wire belts ››Conveying capacity: up to 6,000 t/h ››Conveying speed: up to 65 m/s ››Angles of inclination: up to 30° depending on the material to be conveyed BEUMER PIPE CONVEYORS BEUMER pipe conveyors are closed belt conveyors that reliably transport proBEUMER Belt Conveyors BEUMER Group2024年10月26日 Trough Belt Conveyors A troughed belt is one of the most commonly used conveyors in industrial and mining practices It gets its name from the troughshaped idlers that sit underneath the flat belt The curved shape of What Is a Trough Belt Conveyor and Why You 2024年7月31日 This article delves into what is a conveyor system, not just as a means of transporting items but as a marvel of mechanical engineering These systems enhance efficiency and reduce manual labor across various sectors, What is a Conveyor? A Guide to Streamlining

.jpg)

Transfer Conveyor for Efficient Material Handling

Revolutionize your material handling efficiency with Transfer Conveyor, featuring precisionengineered HONGSBELT Modular Belts This innovative solution ensures seamless 90degree transfers, setting a new standard for efficiency in Conveyor systems designed for liquid material handling frequently use particular belt materials, such as those resistant to corrosion or able to take fluids without leaking Types of Conveyor Systems 1 Belt Conveyors Generally composed of rubber, cloth, or metal, belt conveyors move a continuous loop of material over two or more pulleys Explaining Conveyor Systems: Definition, Function And Uses2023年3月30日 Conveyor belts are also made to be impact resistant, heatresistant and the ability to handle abrasive materials make them suitable for tough applications Working of a Conveyor Belt: Conveyor belts are made up of three key components: the motor, the belt, and the rollers The motor provides the power to turn the rollers, which, in turn, move Conveyor Belt: What is it and How Does it Work? UMS2022年10月1日 In belt conveyors with rigidly mounted idlers, both in the upper and lower belt strand, the next in the series of are set up some time in advance In belt conveyors with rigidly mounted idlers, both in the upper and lower belts, subsequent idlers are set with tilt In practice, this procedure is usually used for every 10 setsTypes and causes of damage to the conveyor belt – Review

Belt Conveyor Design Guide: Quick Tips and Handbook

2024年5月6日 Belt Conveyor Design Guide: Selection and Specification for Optimal Performance In this essential section of the Belt Conveyor Design Guide, we delve into the process of selecting the right conveyor belt for various applications, guided by the conveyor belt selection guideChoosing the appropriate belt type is critical for ensuring the efficiency, safety, 2024年3月15日 A higher coefficient of friction means that less torque is needed to move the belt because the increased frictional force between the belt and drum translates into more efficient motion transfer Conversely, a lower coefficient of friction requires more torque to achieve the same level of motion, as slippage between the belt and drum is more Conveyor Belt Torque Calculation And Load Torque Required2024年5月19日 Conveyor Belt Specification Standards PDF: What is Conveyor Belt Rating What is Conveyor Belt Specification Standards Conveyor belt rating is a crucial factor in determining the performance and durability of conveyor belts in various industrial applications One of the primary ways to ensure that conveyor belts meet the required performance standards is by Conveyor Belt Rating: Key Considerations2023年1月18日 There are three main parts of a conveyor system: the belt support, the pulley and the drive unit Each component plays an essential role in the conveyor unit’s operation While all conveyor systems contain these parts, designs vary in the construction materials and where each component is locatedWhat is a Conveyor System? Definition, Types, Design, and